We all know that the pallet is a very important tool for transportation and warehouse. Today, in fact, there are billions of pallets in circulation every day in the world. This also includes 2 Way Pallet (Stringer Pallets) and 4 Way Pallets (Block Pallets).

Wood Pallet are located in every warehouse and each supply chain around the world. These humble tools have completely changed the way the availability chain works and the way goods are stored and delivered. So today I will introduce the difference between these two. Because if you are not a pallet expert, you will not be able to tell the differences.

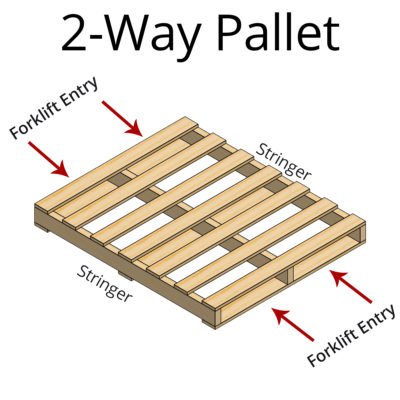

Two Way Pallet (Stringer Pallets)

Two-way pallet is meant to be lifted by the deck plate, with only openings at the highest and bottom, parallel to the pallet stringer plate. The longitudinal beams are horizontal slabs that support the pallet deck.

The pallet is typically arranged with a middle longitudinal beam and two longitudinal beams on all sides . When these stringers are solid and haven’t any grooves, the forklift forks cannot enter the pallet through the side of the stringer.

Two-way pallets allow forklifts to enter from the front and rear of the pallet. They contains stringers. In terms of stacking and space allocation, the power to use a forklift to access pallets from only 2 entry points could also be a drag.

Advantage

- Enhanced durability: The stringers in two-way pallets are solid from starting to end, which suggests they’re stronger and fewer vulnerable to breakage than pallets where the stringers are slotted to make partial two-way pallets.

- Medium load capacity: For an equivalent reasons as above, two-way pallets usually carry more weight than four-way stringer pallets.

- Lower cost: Since the planning of two-way pallets is easier than the planning of real or partial 4-way pallets, they’re easier to manufacture and cheaper to get .

Disadvantage

- Low utilization of warehouse space: two way pallets require a storage arrangement, taking under consideration the very fact that pallet will only be accessed from the front or back.

- Reduce the load: Two-way pallets must be placed within the truck during a way which will be reached by a forklift or pallet jet. The limitation of this loading method means each truck can carry less cargo pallets in one load.

- Reduced supply chain efficiency: Individuals who move two-way pallets must spend time longer working around them to properly lift them, which wastes time and increases operation costs.

Four Way Pallets (Block Pallets)

Four-way pallets have notched stringers or support blocks that allow them to be lifted from any side. These pallets are generally heavier, larger, and more durable than two-way pallets. The more common type between two-way and four-way pallets, four-way pallets are utilized in a spread of commercial and commercial applications.

Four Way pallets with forklifts and pallet trucks that enter from all four sides, which may be an enormous advantage when loading and manipulating pallets. Four-way pallets are favored for his or her heavy-duty capacity and flexibility . There are mainly three sorts of four-way pallets, fully reversible, irreversible and peripheral base pallets.

Their construction is either a fringe base with three plates or an entire perimeter on the bottom . the primary type with three plates is typically called a legged pallet. True four-way pallets are constructed employing a block system to offer them extra strength, they have to be lifted on all four sides.

Advantage

- Highest durability: Among the three sorts of pallets, block pallets are the foremost durable thanks to their design and therefore the high-quality wood commonly used.

- Maximum load-bearing capacity: The static load-bearing capacity of a four-way block pallet is 2,800-3000 pounds, which is above its two-way or partial four-way pallet.

- Improve operation efficiency: Four-way block pallets combine higher durability and strength with the convenience and other advantages of true four-way access.

- Easily be repaired: Four-way pallets are easy to repair so if reuse is an important part of your supply chain plan than a four-way pallet is the best option.

Disadvantage

- Expensive: Of the 2 sorts of pallets, block pallets are the foremost expensive because they require the foremost wood and their design is more complicated.

- Heavy: the load of a 4-way block pallet can range from 25kg-35kg. this may increase the load of a truck pallet, thereby increasing transportation costs.

- Waste of resources: Four-way block pallets are usually made from timber trees. These trees take decades to grow, so it’s impossible to exchange them at an equivalent rate as they’re felled.

Comparing 4-way pallets and 2-way pallets clearly shows that Difference of 2-Way 4-Way Pallet. Each of these types of pallets has its advantages and disadvantages. Choosing one type over the other is to prioritize which pallet characteristics are most important to your company or industry.

When you choose the pallet that suits your operation, considering where your supply chain is traveling is a good starting point. For example, 2-way pallets are indeed standard, so paying the extra costs associated with 4-way pallets may be something you can avoid.